How to 3d print from Solidworks -Designing, Export File

Are you looking for CAD software that can create an STL file format for 3D printing? Look no more as we have found out the perfect software program, and that is Solid Works.

Solid Works is rated as one of the best CAD 3D modeling software program for creating 3D models and objects.

You will find many CAD software in the market, but not all of them all feasible for 3D printing. When it comes to Solid Works, 3D printing is made easy with a number of features and options.

This software allows you to generate 3D models in a way that you can easily get a 3D print of them and providing you a user-friendliness environment.

SolidWorks

As mentioned earlier, Solid Works is a Computer-Aided Design software that allows you to create 3D models and designs. It is one of the most popular software when it comes to building 3D models due to its unique features and characteristics.

SolidWorks has several advantages over other CAD software. The notable attributes of the software include a user-friendly interface, compatibility, efficiency, performance, and effectiveness, and in addition, you can simulate the design as well.

Above all, Solid Works is based on parametric design, which makes it much easier to create and build 3D models without any difficulty as compared to other software programs.

Subscription and Pricing

All the above benefits and functions of this software make the perfect 3D model, but it does not come free. There are versions of this software with different price tags featuring different functions and abilities.

You should know that the software should only be bought from the certified registered reseller in order to avoid any problems in the future.

The reseller may offer discounts and can also give offers based on the functions and features required by the user.

Standard SolidWorks

The standard version of this software covers all the basic functions and features of this program, including productivity tools, animation, and visualization.

Currently, the subscription cost around $1,295 per year, with licensing cost of 3,995 dollars.

Professional SolidWorks

The professional Solid Works version covers the tools and functions which are required at the professional level and are used by experienced designers.

The features mainly include Automatic task scheduling, CAD libraries, stack-up analysis, and batch processing. At this time, it comes with subscription charges of $1,495 with licensing fees of 5,490 dollars.

Premium SolidWorks

As of now, the premium SolidWorks version of this software comes with a subscription charge of $1,995 with licensing fees of 7,995 dollars.

In addition to the features as mentioned above, it mainly includes advanced surface flattening, Routing, and motion analysis.

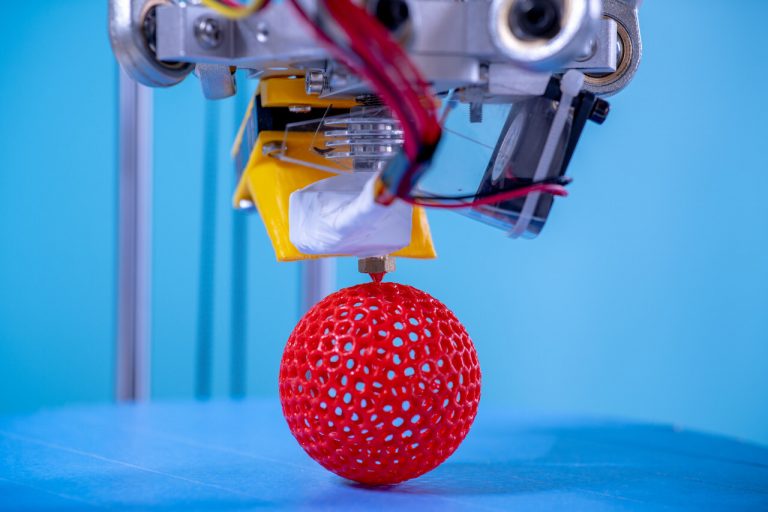

3D printing with SolidWorks

Solid Works software is capable of creating an STL file, which is used by the 3D printers to print 3D models.

Solid work software offers you a number of parameters to adjust the 3D model correctly, and it prints without any distortion and warping.

The settings and parameters need to be considered carefully as they directly affect the overall quality of the print result. Plus, it should be applied to the 3D printer you are going to use.

In order to get the perfect 3D print, you should be familiar with the Solid Works software first, and therefore you should proceed with 3D printing if you are familiar with the software.

As you know that it is a paid software; therefore, professionals are recommended to go for this program.

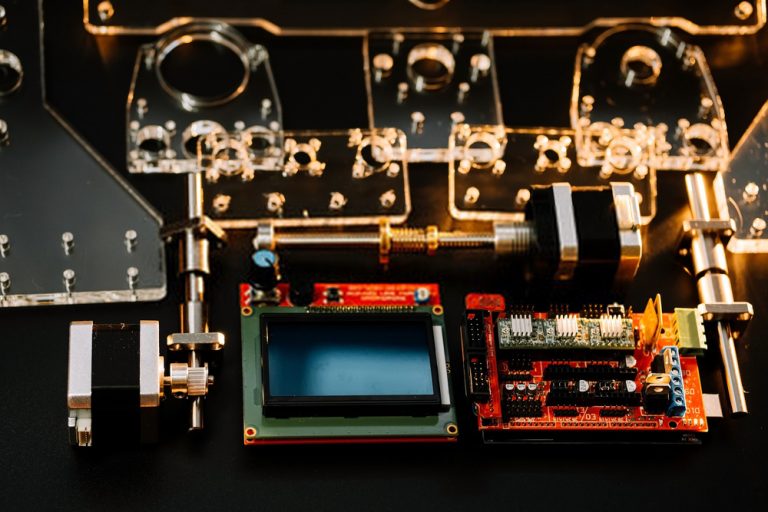

Designing a printable 3D file

When working on SolidWorks, designing a 3D file involves modeling with correct dimensions and volume, surface modeling, and adding text or coloring for a 3D print.

When modeling a 3D design, using SolidWorks for 3D printing gives you two types of modeling, Solid and Surface; you can work on one kind and as well as combine both and can work at the same time.

On the left side of the screen, you will see a scroll down menu where you can see all the available bodies.

In order to get the 3D print, the surface model needs to be converted into a solid before exporting, and for this, your surface bodies require to be sealed with continuous, standard, and finite borders.

With a hollowing function, you can create a hollow object if required. It will also save your material and will eventually reduce the production cost.

Once you are done with the designing phase, the software allows you to measure the dimensions and distances with a tool called “Measure” so that you can change it before it starts printing. The information tab, on the other hand, gives you all the details of the specific file.

Export File

Now, all you need to do is to make an STL file so that it can be sent to the 3D printer for print. For this, select the “save as” option, and then under the “type” section, select .stl file type.

Before saving the file, the screen will show you the different setting parameters that can affect the quality of the result.

The two main vital elements to check here are deviation and the angle. Both of these factors play an essential role in the accuracy and precision of the print result.

You will also be able to see a preview of the model before you save the file; therefore, check all the elements carefully so that your time and resources are not wasted, and you get the perfect result in the end.

Common mistakes such as file too large, merging volumes, etc., can be avoided if the parameters are carefully chosen.