How long does a 3D printer nozzle last?

Owning and working with a 3D printer is not as simple as it sounds. Surely it has a great many benefits once you learn all about it, but it also requires your time and effort for proper and prolonged functioning.

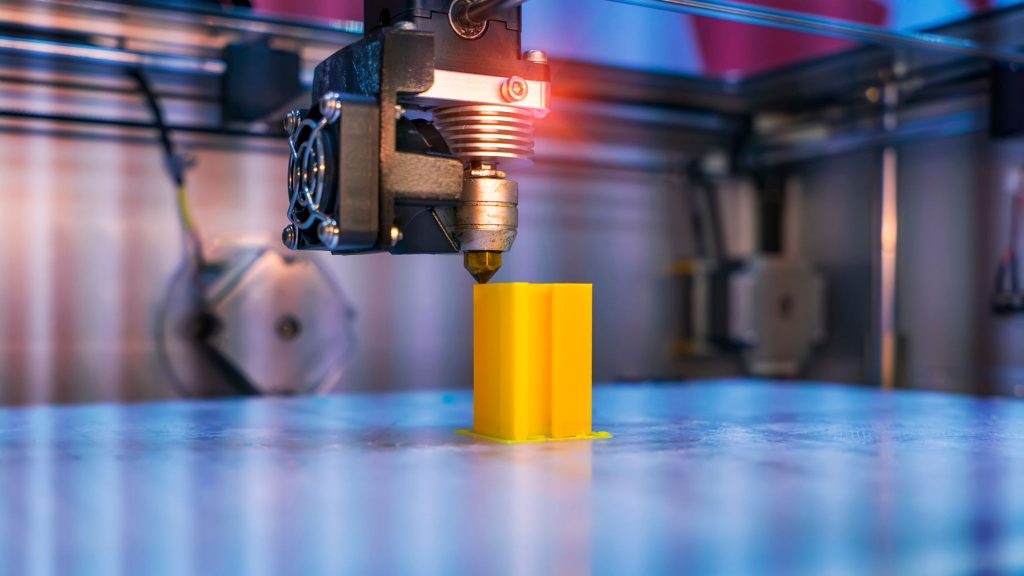

Among the additional costs and problems that come along with the 3D printer, one of the most common troubles many users encounter is the 3D printer’s nozzle. The 3D printers’ nozzles wear out after some time and the printing quality gets poor and the products lack a smooth finish and a neat look after completion.

Nozzles play a huge role in the proper functioning of 3D printers as they impact the quality of the product and if you want smoothly finished products, you will have to invest time and effort in the regular replacing and maintenance of nozzle, especially if you are using the brass nozzle because it requires additional care.

Now you might be wondering what is the best time to change the 3D printer’s nozzle and how often you should do it. Well, the straight answer is, it depends on different factors.

The filament you use, the hours your printer runs in a day, and the brand of your printer, all these factors contribute to the determination of how often the nozzle should be replaced.

Some people use PLA filament while others prefer Polycarbonate. Polycarbonate is an abrasive filament and the nozzle can wear down rather quickly if the filament is abrasive. So in this case, users are advised to use hardened steel nozzles.

In this article, we are going to look into different factors that determine how often you should change the nozzle of your 3D printer, and if you have a similar question, keep reading to find out the answer.

Nozzle Type

The lifespan of the nozzle is determined by the type of nozzle you are using and the hours your printer runs every day. Nozzles are usually brass, ruby-tipped, or steel.

If you use a printer once or twice a week, then a brass nozzle will last for 3-6 months, but if your 3D printer runs 24/7, you will have to replace the brass nozzle every month.

Stainless steel nozzles last around for a year and the ruby nozzles are the most reliable, lasting for years.

Why Should You Replace Nozzles?

The printing quality of a 3D printer gets affected over time by different factors, such as leveled print bed, nozzle health, and a few others. Therefore, keeping track of work hours and performance of the printer’s nozzle is very important but it helps you in determining the right time to change the printer’s nozzle.

Printers’ nozzles deteriorate over time by constant use, which is nothing to worry about. The type of filament you use for printing also has a major impact on the serviceable life of the nozzle because non-abrasive materials such as PLA are not as harmful to the nozzle as abrasive materials like Polycarbonate are.

If your printer’s nozzle has started to deteriorate, you will notice a difference in the print quality. Print quality is directly related to the health of the nozzle, so if one goes down, the other follows suit.

The worn-out nozzles are not suitable to print filaments as new nozzles do so it is better if you learn how to test and detect your nozzle’s health.

Apart from the nozzle’s health, different other factors can affect the quality of a 3D print. One such factor is the level of the print bed, which, if placed incorrectly, creates a lot of trouble.

So if you want to maintain a consistent printing quality, it is important to ensure that all the variables are in line, because only if one gets out of line, it will affect the printing quality. You also need to keep a track of your printer’s nozzle health and its serviceable life.

Problems of a Worn-Out Nozzle

The printing quality is diminished if the diameter and fluency of an extruded plastic material are altered in any way. The effect is there even if the change is slight.

The more a printer’s nozzle is worn out, the more declined quality of the print will be the outcome. And it does not happen only because of nozzle clogging, but the extruded filament also varies in diameter and adds to the poor printing quality.

The nozzle getting clogged is a major concern for 3D printer users, and it usually happens due to excessive exposure to high temperatures and radiation over time. It also depends on the type of filament being used and carbon build-up, which acts as an abrasive inside the nozzle.

Inside the nozzle, there are groves, which slowly increase in diameter and provide opportunities for clogging to take place in the nozzle.

Moreover, with time, dirt and dust settle down on the filament roll which burns inside the hot end of the nozzle and adds to the carbon build-up which further narrows the extrusion diameter of certain nozzle areas and causes clogging while deteriorating the print quality.

A printer’s worn-out nozzle also affects the Z coordinate because of changes appearing in the nozzle features. As a general rule of thumb, the height of the Z coordinate should not be higher than the diameter of the nozzle, and it also should not be lower than the quarter of the nozzle’s diameter.

The print quality of a 3D printer also depends on the accurate Z height, the right melting temperature for the filament at the hot end, the level of printing bed, accurate temperature if you are using the heating bed, correct and fluent diameter extrusion, and few other variables such as printing speed.

All these factors collectively allow for a fluent and uninterrupted layer upon layered printing. Worn-out nozzles result in print complications and often result in total failures.

How to Know About the worn Out Nozzle?

One of the easiest and most useful ways to detect the nozzle serviceable life is to print a small piece of filament with the currently used nozzle and print another piece with a new nozzle. Compare the difference between both prints.

You will indicate quality differences from both results. However, the ideal condition will be to run both tests simultaneously: make the first print with the worn-out nozzle, and the second with the new nozzle, and compare both the prints.

Another thing you should practice is to check the inside of the nozzle to see if it’s worn out because most of the nozzle deterioration begins from its inside. Internet deterioration leads to uneven extrusion and uneven clogging on the nozzle, which affects the print quality of the product.

Here is another test you might want to carry out. Look at the shape of the tip of the nozzle; if the tip has become rounded, you should replace the nozzle very as soon as possible. Because the nozzle tip should be free of chips, nicks, accumulated materials, and look sharp.

How Do Nozzles Get Damaged

Some 3D printers are fitted with cheaper nozzles because these nozzles do not cost much and bring the overall price of a 3D printer down. The standard nozzle type in most printers is brass, which is a soft metal and susceptible to getting damaged after a few prints.

But the plus point of brass nozzles is that these have the best thermal characteristics and are very suitable for 3D printing. They retain and conduct heat consistently heat which is optimal for 3D printing.

Printing with more abrasive and harder metals like polycarbonate, carbon fiber, composite filaments, nylon, and some brands of glow-in-the-dark filaments will cause more stress on the nozzle. Consequently, the nozzle will wear out much sooner, so it is better if you stick to the PLA filament.

This also reduces the lifespan of your printer nozzle and the only option you are left with is to replace the nozzle after some time with a better quality nozzle.

Stainless Hardened Steel Nozzle

If you plan to use abrasive printing filaments or print food-safe items, then we recommend you use stainless steel nozzles. Stainless steel is a relatively harder metal than brass and can easily withstand abrasive materials for quite a long time.

FAQs:

When should I replace my 3D printer nozzle?

There is no set time frame to replace your printer nozzle, but it is recommended that you should change it every 3 to 6 months for better working of the printer.

How long does a nozzle last with PLA?

If you have a brass nozzle in your printer, then it can easily work on the standard PLA filament for a year or more.

How do I know if my 3D printer nozzle is bad?

You should look inside the walls of the nozzle. The marks and groves in the inner walls of the nozzle indicate whether the nozzle is worn-out or not. The nozzle’s diameter also becomes bigger than usual as well as its tip becomes round and dulled down.

However, if the filament is abrasive, then y6ou will have to choose a ruby-tipped nozzle or stainless steel as these metals are harder than brass and do not wear out easily.